In the complex world of freight rail operations, railcar visibility is no longer a luxury—it’s a necessity. Rail shippers, lessors, and operators are under increasing pressure to improve operational efficiency, maximize the use of their fleets, and deliver value to their customers while controlling costs. Yet, without accurate data on the load status of individual railcars, decision-making often relies on assumptions, manual updates, or outdated systems.

That’s where Load Status Monitoring through telematics comes in—a powerful tool that gives stakeholders real-time visibility into whether a railcar is loaded or empty, enabling smarter decisions across the supply chain.

The Value of Knowing Load Status

At a glance, load status might seem like a simple data point: either a railcar is loaded or it’s not. But that single data point can drive a wide range of strategic decisions across rail operations. From reducing dwell time to improving lease management, load status is a critical lever for:

- Improved railcar utilization: Knowing which railcars are loaded or empty in near real time allows operators to redeploy assets faster, avoid unnecessary empty runs, and ensure every car in the fleet is contributing to productivity. It helps match capacity to demand, ultimately reducing the number of underused or idle cars.

- Reduced delays and empty moves: Empty railcars mistakenly sent to customers or routed across the network waste fuel, time, and resources. With load status monitoring, operators can catch these errors early and avoid unnecessary moves, helping to streamline logistics and reduce waste.

- Better yard and terminal planning: When yard managers have access to accurate load status, they can prioritize loaded cars for departure and plan space more effectively. This contributes to reduced congestion, shorter dwell times, and improved efficiency in terminal operations.

- Real-time supply chain coordination: Load status data can be shared with shippers and logistics partners to align transportation schedules and warehouse staffing with actual conditions. This visibility improves coordination and helps reduce costly delays or idle labor at destination facilities.

- Accurate billing and auditing: In some operations, loaded cars are billed differently than empties. Accurate load status ensures proper invoicing, supports contract compliance, and reduces billing disputes between railroads, shippers, and third-party logistics providers.

Without reliable insight into whether railcars are loaded or empty, it becomes difficult to manage turnaround times, predict availability, or track underutilized assets.

Challenges Without Load Visibility

Before the adoption of telematics and automated sensors, railcar load status was often updated manually or inferred based on scheduled events (such as loading/unloading). This traditional method is not only time-consuming and error-prone but also fails to reflect real-time changes in the railcar’s status.

Some of the key challenges rail operators face without accurate load status monitoring include:

🚫 Railcars sent empty by mistake: Without real-time confirmation of load status, it’s possible for railcars to be mistakenly dispatched empty. These errors result in wasted trips, lost revenue opportunities, and increased network congestion—adding avoidable costs to operations.

🛑 Underutilized fleets: Railcars may sit at yards or customer sites without being moved because their status is unknown. In large fleets, even a small percentage of idle but usable cars can represent a significant drag on productivity and ROI.

⚠️ Inefficient routing decisions: When load status is unclear, dispatchers and planners may misallocate assets—sending loaded cars to the wrong location or routing empty ones on priority lines. These inefficiencies affect both the cost and timing of deliveries.

🔄 Difficulty in reassigning assets: Operators hesitate to reassign a car if its status is uncertain, fearing delays, double handling, or customer dissatisfaction. This slows responsiveness and creates delays in meeting new or urgent shipping needs.

💰 Billing discrepancies: Inaccurate load status records can lead to incorrect billing, missed revenue, or customer disputes. Whether billing is usage-based or tied to load movements, verified load status is essential for transparency and financial accuracy.

How Telematics Enables Load Status Monitoring

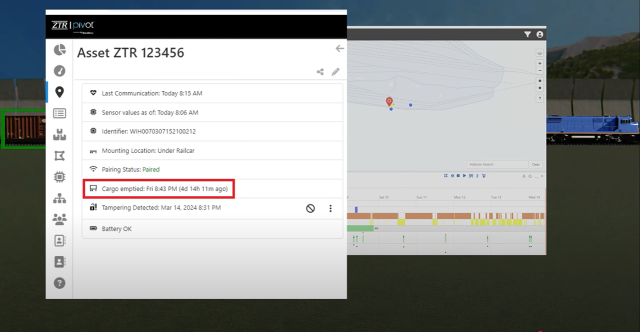

Modern telematics solutions like Pivot by ZTR use wireless sensors such as the Pivot Load Sensor to detect and transmit whether a railcar is loaded or empty. These sensors are installed on the car body and detect changes in load weight. The data is sent to a central IoT gateway—like the Pivot Gateway—which then transmits it securely to an online monitoring platform. The following video provides a good overview of how load status monitoring works.

Key characteristics of this system include:

- Near real-time updates on load changes

- No manual data entry required

- Intuitive and easy to use digital platform

- Alerts and notifications when a load status unexpectedly changes

Maximizing Utilization through Load Insights

With load status data readily available, fleet operators can dramatically improve asset utilization. Here's how:

🔁 Reduced Turnaround Times

Knowing exactly when a railcar is emptied allows for faster redeployment, minimizing idle time and enabling more shipments with the same fleet size.

🚂 Efficient Routing

Loaded railcars are prioritized on main lines while empty cars can be staged or rerouted for loading. Real-time data allows better train makeup and network optimization.

📊 Data-Driven Leasing and Repositioning

Lessors and shippers can analyze patterns of underutilized railcars and make informed decisions about reallocating or retiring cars not performing as expected.

📦 Improved Planning & Yard Management

Yard managers benefit from knowing which cars are ready to move and which are still waiting to be unloaded, ensuring better staging and dispatch planning.

Fleet Optimization with Load Status Data

Beyond individual car utilization, load status plays a key role in fleet-level optimization. Over time, aggregated load data enables:

📉 Identifying Underperforming Railcars

With accurate load data over time, fleet managers can pinpoint railcars that are consistently underused or idle. These insights help identify problem areas in the network, inefficient customer sites, or cars that may no longer be needed—enabling data-backed decisions on redeployment or divestment.

⚖️ Balancing Fleet Capacity Across Regions or Business Lines

Some regions or customer segments may have excess railcar availability, while others are experiencing shortages. Load status visibility allows for proactive fleet balancing, ensuring each area has the right number of cars to meet demand—without overcommitting valuable assets.

🛑 Avoiding Over-Investment in Additional Assets

When you don’t have a clear picture of how your current fleet is being used, it’s easy to fall into the trap of acquiring or leasing more cars than necessary. Load status data ensures that investments in new railcars are made only when justified by utilization trends, helping avoid unnecessary capital or lease expenses.

🔁 Optimizing Empty-to-Loaded Movement Ratios

Empty railcar movements add cost without generating revenue. Monitoring load status across moves allows operators to minimize empty legs, improve route planning, and create more efficient round-trip cycles—boosting the overall productivity of each railcar in the fleet.

Fleet managers can make smarter capital decisions and reduce reliance on “gut feel” or overbuffering inventory.

Turning Insights into Action

Railcar load status might seem like a minor data point, but in the context of fleet and supply chain management, it is an essential operational insight. Solutions like Pivot give rail stakeholders the tools to not only track railcars in near real time, but to understand what each railcar is doing—and whether it’s working for your bottom line.

By integrating load status monitoring into your operations, you unlock a more responsive, data-driven approach to railcar management that improves efficiency, reduces costs, and enables smarter decisions at every level.

Fill in the following form to see Pivot in action.